Fire water mains

Fire water mains are critical assets for industrial complexes such as chemical plants and refineries, since they are highly safety-related.

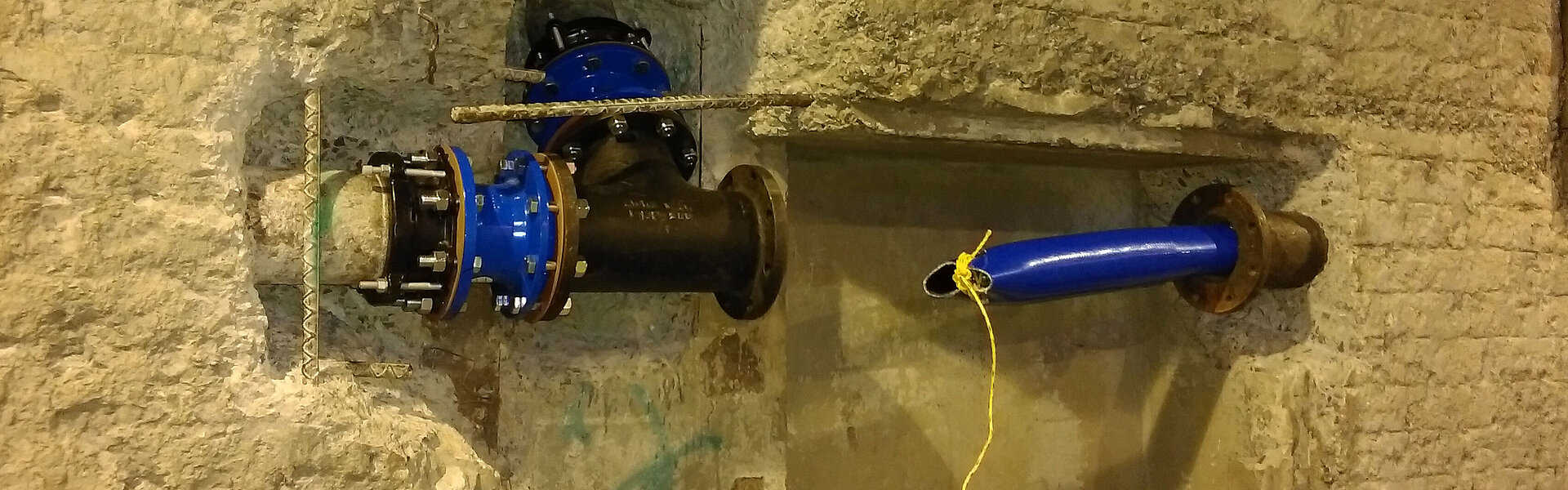

In ageing plants, however, the smooth operation of these fire water mains is often affected by corrosion and pipe degradation. Failures may have catastrophic consequences, making maintenance of these assets indispensable. The rehabilitation of fire water mains often poses great challenges for the operator: High pressure rates of up to 16 bar, accessibility of the line through overlapping other pipes and power cables, encasement in concrete and, above all, safety regulations during the renovation make the work significantly more difficult.

A short downtime is important for continued plant operation. Primus Line® can help to overcome these hurdles: Short installation times with minimal space requirements as well as small excavation pits, high liner operating pressures, which are accommodated independently of the host pipe and at the same time a low liner wall thickness represent the ideal system for the rehabilitation of critical infrastructure such as fire water mains. Primus Line® has already proven its advantages in this area.

Challenges for operators, advantages of trenchless methods and realised projects

When rehabilitating fire water mains, operators are confronted with both technical and economic challenges. Which are these and what are the advantages that trenchless systems offer?

Trenchless methods are a recipe for success in the rehabilitation of fire water mains. Which ingredients are involved and in which projects has Primus Line® already proven its benefits?