Primus Line® Overland Piping is the consistent further development of a technology that Rädlinger primus line GmbH has been using for more than 20 years for the trenchless rehabilitation of pressure pipes. The Bavarian company’s above-ground solution is now also being used all over the world, for example in France, Canada and Norway, to reliably transport brine, domestic sewage and process water.

In all of these projects, the flexible pipeline based on the aramid-reinforced liner has prevailed over above-ground HDPE pipes, albeit for different reasons.

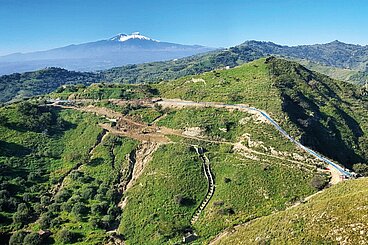

These include significant advantages in terms of mobilisation and equipment requirements. The fabric-reinforced liner is transported on reels, saving space. Installation requires a mini-excavator or winch and simple hand tools. There is no need for machinery, manpower or time spent on complex welding to make the connection. Installation and dismantling times are correspondingly shorter. Primus Line normally take one or two days to lay six kilometres of their liner. Lengths of 1,000 metres and more in one section reduce the number of joints and weak points. The liner easily adapts to the unevenness of the surface. By comparison, installing the same length of HDPE pipe takes about 25 to 30 days, with increased additional labour costs. Dismantling the same length of pipe also takes only one to two days with Primus Line® Overland Piping, as the liner is simply rolled up, compared with seven to ten days for HDPE. The subsequent storage requirements for HDPE pipes are up to ten times greater than for liners on reels. In addition to storage and transport costs, operating costs are on average also lower due to minimal mobilisation and demobilisation costs and lower manpower requirements.

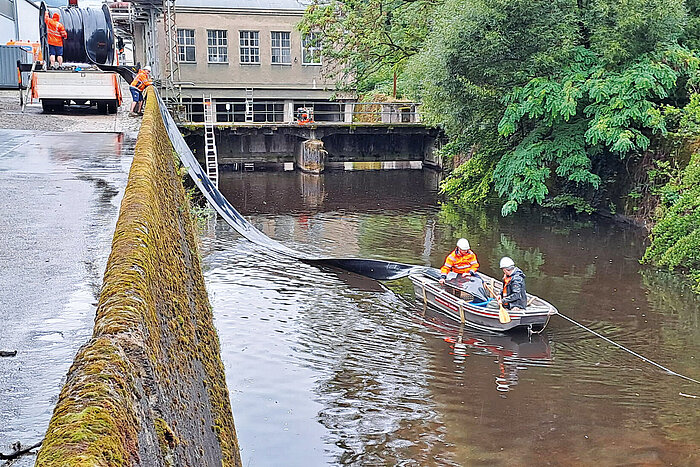

In addition to cost and efficiency, the low use of machinery also contributes to the environmental friendliness of the Overland Piping system. It can be installed in sensitive environments such as protected areas, nature parks or rivers without major environmental impact. This avoids emissions and reduces the carbon footprint.

The middle layer of the three-layered Primus Line® Overland Piping system ensures the safety of the flexible pipe: It is made of seamlessly woven Kevlar®. This synthetic fibre is up to ten times stronger than steel and twice as strong as glass fibre or nylon. The flexible pipe therefore has a very high factor of safety (FoS). The burst pressure is at least 2.5 times higher than the allowable operating pressure. The entire production process is closely monitored. Sensors and cameras continuously capture the process parameters and provide the basis for extensive wall thickness and consistency control mechanisms. In addition, every liner produced is subjected to an in-house pressure test before being delivered to the construction site.