Installation process

One main benefit of Primus Line® Overland Piping is its simple, fast and safe installation that requires only few tools, welding work or after-treatment of the liner. This also enables an installation with only little environmental impact in sensitive environments like nature parks or waters. After use, the system is just cleaned and rolled up. It is now ready for its next use.

Installation

Installing the hauling rope

To lay the liner, a hauling rope (steel cable or sling) is mounted at one end.

Laying the liner

The liner is delivered on a transport reel. It is laid in the field by means of a cable winch, a mini-excavator or directly from a lorry. Prior to this, the terrain has to be checked for sharp objects.

Mounting the connectors

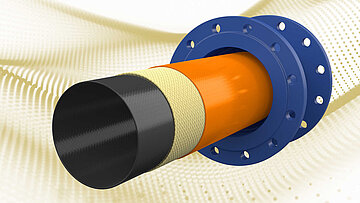

Mounting M-Connectors with flange

Primus Line's M-Connectors consist of a bushing, a sleeve and a core. Purely mechanical forces create a tension-resistant connection between the liner and the connector. This is achieved by pressing the core into the sleeve using hydraulic tools.

Mounting Q-Connectors (compatible with Victaulic coupling system)

Primus Line's Q-Connectors are mounted in a similar way to M-Connectors. Temporary flanges are used for this purpose.

Pressure test

The pressure test in accordance with relevant rules and regulations for liquid media ensures the stability and especially leak-tightness of the Primus Line® pipe.

Connecting the line

To enable the pipe to be put into operation, it is connected to the pipe network, a pump, fitting or similar via the mounted connectors or by installing a fitting piece. With the M-Connector, the connection is made by screwing the flanges together. The Q-Connectors are compatible with the Victaulic coupling system and can therefore be flexibly connected to a wide range of other compatible components.

Uninstallation

Decommissioning the pipeline

To uninstall the Primus Line® Overland Piping system, the pipeline has to be taken out of service and drained.

Disassembling the connectors

A second connector core and hydraulic tools are used to press the connector core out of the sleeve.

Installing the hauling rope

A hauling rope (steel cable or sling) is mounted at the end of the liner.

Winding up the liner

The liner is pulled back with the help of a cable winch or an excavator. Then it is wound up on the transport reel supported by an electronic motor at the reel. In this process, it is visually inspected and cleaned, if necessary, before its next use.