Efficient and traffic-friendly solution

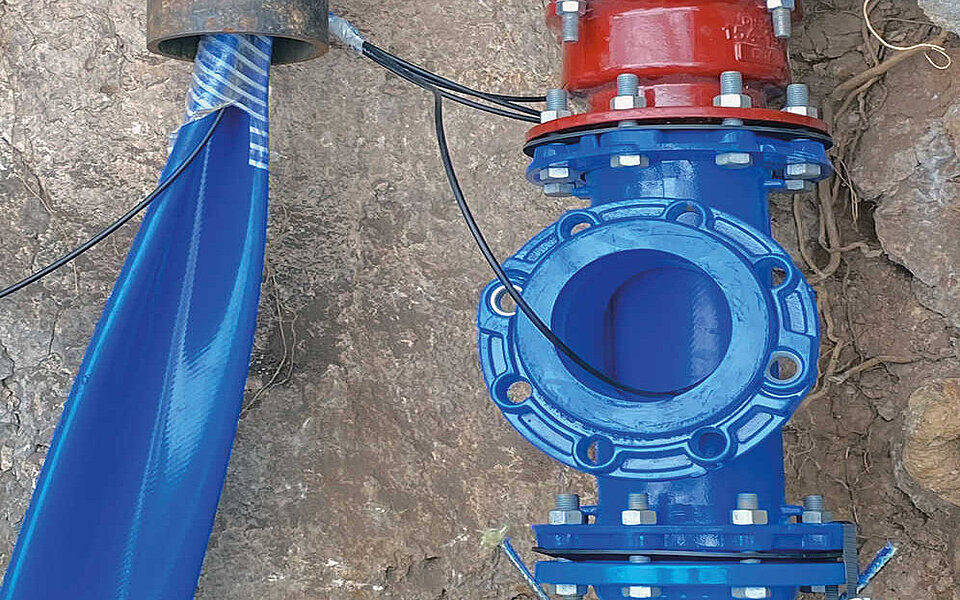

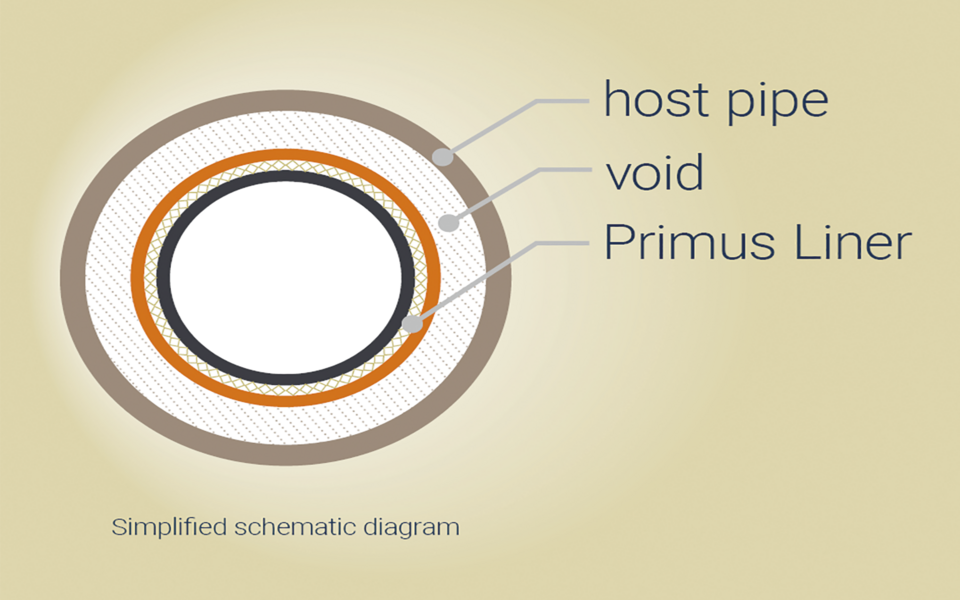

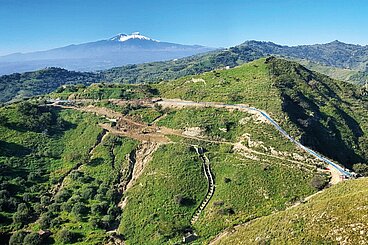

The DN 150 grey cast iron drinking water pipeline with a cement mortar lining was rehabilitated on behalf of Société Monégasque des Eaux, Monaco's water supply company. The Primus Line® Rehab System DN 150 PN 56 was used in two parallel pipes, each with a length of 55 meters. The Primus Line® Rehab System DN 150 PN 56 was used in two parallel pipes, each with a length of 55 meters. It had to be ensured that a maximum flow velocity of 3.25 metres per second was not exceeded. Each section was pulled in through two 45-degree bends, one 22-degree bend and one 11-degree bend. The camera inspection in advance revealed heavy incrustations in the pipes, which made intensive and time-consuming cleaning of the pipes necessary. The pipes were inspected and cleaned in advance using a camera inspection. With the installation of the special Primus Line connectors for connection to the pipe network and the final pressure test, the installation took two weeks.

An open renovation would not have been an option due to the complex pipe route along the main traffic artery, the ‘Boulevard de la Turbie’, and the important pedestrian path, the ‘Escalier du Mont-Agel’ staircase. The installation of the Primus Line® trenchless rehabilitation technology had hardly any impact on traffic. Both the road and access via the stairs remained open to traffic and pedestrians throughout the entire construction period.