This was the question utility services supplier, Hunter Water, asked as it needed to maintain an optimum water supply to the second-largest city of New South Wales.

The mild steel cement-lined pipeline DN 900 PN12 runs underneath a busy street and a highway access and has two opposing bends of 22.5 degree. Works had to be conducted with only two access points. Rehabilitating the pipeline using a traditional dig-and-replace method would have caused road closures for several weeks, affected the environment and disrupted nearby residents.

To overcome the myriad of challenges associated with this project, Primus Line® was selected: Its flexibility allows the Primus Line system to be installed through consecutive bends of up to 45 degrees. The robust liner can also withstand bends of 90 degrees, depending on the characteristics of the pipeline.

Upon investigation, Primus Line developed two options for rehabilitating the trunk main:

- Installing one Primus Liner DN 500 PN 16 with an inner diameter of 452 mm would grant Hunter Water a utilisation of under 25%.

- Installing three Primus Liners DN 450 PN 16 with an inner diameter of 396 mm would grant Hunter Water a utilisation of nearly 60%.

The section of the pipeline that required rehabilitation was only approximately 140 metres. Moreover, the friction coefficient of the Primus Liner is with a K-factor of 0.028 lower than the friction coefficient of the existing main. The results of Hunter Water’s calculations finally showed that a reduction in diameter would be acceptable. In the end, the utility service supplier decided to rehabilitate the pipeline with the Primus Line 3-in-1 solution to obtain a higher utilisation.

Installing three Primus Liners DN 500 was not an option, as the liners could not fully inflate inside a DN 900 host pipe. A minimum inner diameter of 1000 mm or greater would have been necessary.

Hunter Water assigned the installation of the project to Interflow, a business that is renowned for pioneering the trenchless technology space and is the most experienced Primus Line installer in Australia to date.

The existing pipeline was extended at both ends with a customised reduction piece DN 900 to DN 1600, which created space for the three Primus Line flanges. The reduction, as well as the manifold, were designed by Primus Line and produced locally by Hunter Water.

The Primus Liner was transported on three reels to the construction site. These were placed sequentially behind the start pit in line with the run of the pipeline. Each liner was marked with tape of a different colour to ensure that after insertion, the hoses were at the correct positions at both ends of the pipe. During insertion, the liners were combined and stacked, then fixed with tape to keep their shape.

After insertion by means of a pulling winch, Primus Line’s installation partner, Interflow, threaded the liners through the manifold and brought them into shape one-by-one with compressed air.

Following the inflation process, the six Primus Line connectors could then be installed. The entire installation of the Primus Line® system was completed within one week. A separate pressure test with 15 bar was conducted for each liner. This trenchless method enabled the region’s busy traffic flow to continue smoothly, and residents could go about their day-to-day activities with minimal disruption.

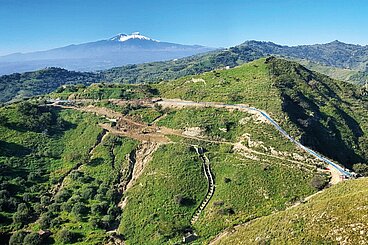

This 3-in-1 Primus Line solution was the first to be implemented outside Europe. Rädlinger primus line GmbH has already proven its excellence for multi-liner installations in several projects. Inter alia in Sicily, Italy, where a comparable solution has been in operation since 2017 and garnered worldwide attention at the time of putting it into service.