Karriere

Benefits

Environmentally orientated

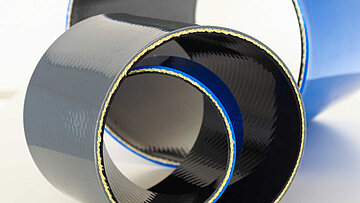

- Waste reduction due to reusability

- No heavy equipment

- Eliminating CO2 emissions by heavy lorries during operation for the transport of liquids

- Installation in sensitive environments like nature reserves or bodies of water is possible with minimal environmental impact

- We also pay attention to sustainability as a company