In addition to this, an independent, external testing laboratory supervises in semi-annual checks the compliance with the own company standard and the standards fixed in Technical Rule VP 643 which are the prerequisites for the DVGW type examination certificate.

At goods receipt

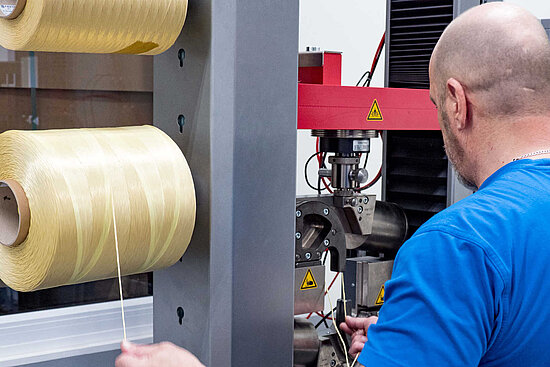

“We apply high standards already when selecting raw materials and only cooperate with renowned manufacturers. We examine incoming goods such as the thread from which the liner is woven or the plastics for coating carefully for their quality”, explains Christian Schwarzfischer, responsible for quality control and development. To do so, every batch is checked thoroughly and the results are matched with the certificate of the manufacturer. The thread tension test, for example, checks the strength and stretching of the thread and the MFI check (melt flow index) examines the flow behaviour of the plastic.

Christian Schwarzfischer

Incoming goods inspection also affects the specifically developed connectors that are inter alia manufactured by a sister company of Rädlinger primus line GmbH. Apart from a dimensional check and a visual inspection, their functionality will be examined in regular intervals as well. In order to check the welding quality, a burst pressure test will be carried out. To do so, water is pressed into the connector until it bursts.

During pre-production

Before the actual production of the liners starts, the production line is set up. There are three production lines available in the factory whose architecture was specifically designed for Primus Line® production. The liner is produced vertically via four floors by means of a particular circular loom and corresponding extruders for coating. “Depending on coating, field of application and diameter, there is a special formula for each product,” says Christian Schwarzfischer. “Each formula consists of about 300 parameters which will be continuously controlled during the later production.” When the parameters are set, a first test piece can be produced. During the burst pressure test for proving its strength, this piece will be subjected to water pressure until it bursts. “After that we can actually be sure that we are producing a high-quality product,” Christian Schwarzfischer is convinced.

During ongoing production

But Primus Line does not want to rely on this. So the production itself is subject to a continuous control with optoelectronic and optical measuring devices. They capture all process parameters and permit permanent control of quality and wall thickness of the individual liner layers.

If a process parameter exceeds or falls below its limit values, the line will instantly signal this to the operator via an optic or acoustic signal or the line will even be shut down, if necessary, to enable timely error rectification.

The last piece of the produced liner is re-checked for the required product parameters. In addition, also the process parameters will again be checked in detail for anomalies and evaluated.

During shipping and transport

If the product has also passed this step of quality control, an acceptance test certificate 3.1 according to EN 10204 is issued that will be handed over to the customer. The liner is either stored until delivery or picked directly. Before shipping, most of the liners are pre-folded in U-shape for insertion. During this slowly progressing procedure, the operator will optically re-inspect the entire length.

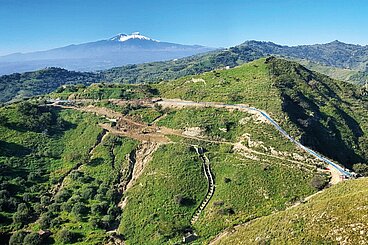

Depending on the route of transport and/or the accessibility of the construction site, the liner is protected on its transport reel by aluminium cladding. However, this is only necessary in very few cases.

The quality formula

“In the end, permanent monitoring and control are the fundament for our high quality standard. This actually even goes beyond the process from goods receipt to delivery. We are constantly trying to improve and therefore, when developing new products, we always consider how we can ensure their quality,” says Christian Schwarzfischer about the way of thinking in the “Research and Development” team.

The high quality standard of Primus Line® not only aims at customer satisfaction. What is even more important is the responsibility to reliably supply many thousands of people as well as the leak-proof operation of every water, gas or oil pipeline without losses or environmental impacts.

The own construction site teams in Germany and Austria as well as the international partner companies, who are specially trained and certified for the installation of Primus Line®, are also aware of this and continue to apply the quality standard during installation.