30 May until 3 June 2022

Stand C3.217

30 May until 3 June 2022

Stand C3.217

The new low-pressure liner serves pipes with a nominal width of DN 400 and, with a permissible operating pressure of 12 bar (MOP), aims in particular at applications with a pressure rating of PN 10. The need for rehabilitation of wastewater pressure and drinking water pipes in precisely this area has recently increased significantly.

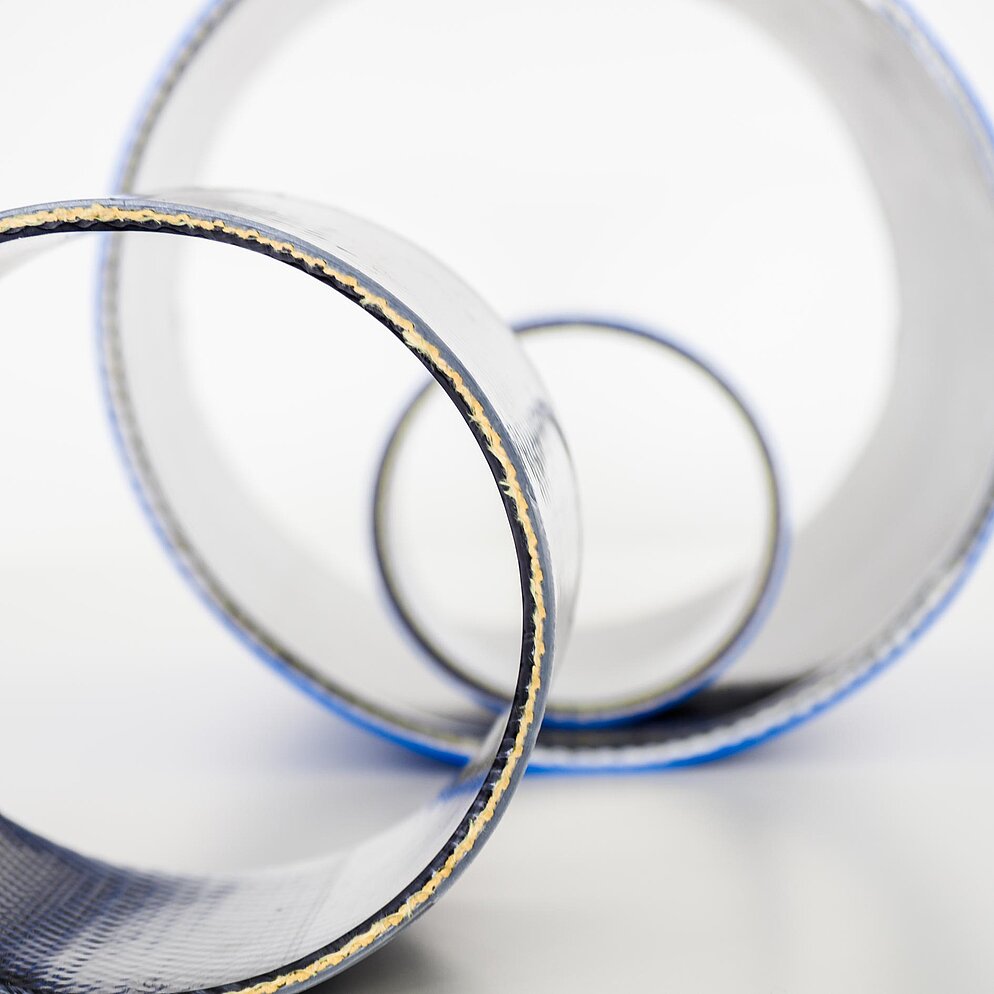

Primus Line can thus once again offer a safe and economical rehabilitation solution, even for lower pressure levels. The low-pressure system is a cost-benefit-optimised version of the medium-pressure system. Through the targeted reduction of the aramid share in the fabric layer of the liner, cost savings of up to 30 percent were achieved in the case of the DN 400.

Products for diverse applications

With the low-, medium- and high-pressure system, the company has a differentiated portfolio that includes a custom-fit solution for a wide range of applications. In addition to the medium water, the technology is also suitable for gas and oil applications and can also be installed as a bypass due to its flexibility combined with high material strength. With over 1,500 completed projects worldwide, the company has experience in a wide range of applications, including large-scale projects with long insertion lengths.

Due to its features, Primus Line® can do even more than purely special applications in the form of culverts or crossings of bridges or traffic routes. Last year, for example, Primus Line rehabilitated a 1.2 kilometre long DN 300 grey cast iron drinking water pipeline in Zweibrücken in two sections. On the Italian island of Sardinia, a six kilometer long rehabilitation project on a DN 500 drinking water pipeline made of asbestos cement was completed in 2020. The longest section pulled in there covered more than 1.1 kilometres and took only three hours at a pull-in speed of about six metres per minute.

Project in Sardinia: The longest section of 1.1 kilometres was installed in just three hours.

Designed for long rehabilitation sections

Primus Line® is designed for exactly this purpose: for long rehabilitation sections, transport pipelines and transmission lines. Pipeline lengths of up to 2,500 metres in one section can be rehabilitated with Primus Line®. Produced can even be up to 4,500 metres in one piece.

The Primus Liner is completely prefabricated in the production plant according to ISO 9001 standards and delivered ready for installation - seamlessly and under continuous quality control. This not only reduces the installation time on site, but also increases the safety and quality of the product with a service life of at least 50 years. Risks that arise with alternative renovation methods due to improperly executed welds or pre-assembly under difficult conditions on the construction site are eliminated.

Nevertheless, Primus Line® remains flexible for many unforeseen situations. Smaller pipe offsets, bends of up to 45 degrees, deviating materials or valves to be passed through, which only become apparent during the construction of the excavation or during the camera inspection, hardly pose a project risk. The flexibility of the liner and the annular space that remains between the liner and the old pipe make the rehabilitation solution independent of many external conditions. Time and costs therefore remain within bounds, even in the event of unexpected conditions.

Haptic experience and strong team presence

Visitors to IFAT will also be able to see this for themselves. At the company's stand, the haptic experience of the products will play a particularly important role. First and foremost, the broad-based trade fair team with technical experts and regional contacts is looking forward to meeting all customers in person and discussing specific project plans or application scenarios.

Here you will find more information about our trade fair appearance and our trade fair team. You can also make an appointment with our contact persons in advance.

To the Primus Line IFAT page

Stay up to date with Primus Line: Subscribe to our newsletter now!

Information about sending newsletters with the provider CleverReach, evaluation, and your unsubscribe options can be found in our privacy policy.

What challenge are you facing? Let us know how we can support you!