The North Head Wastewater Treatment Plant is the second largest of the wastewater treatment and water recycling plants in greater Sydney, the Blue Mountains and the Illawarra and serves about one million people. The majority of North Head’s processing is completed underground. The core of the plant is based in tunnels and subterranean chambers located up to 100 metres below the surface of the Sydney Harbour National Park in Manly.

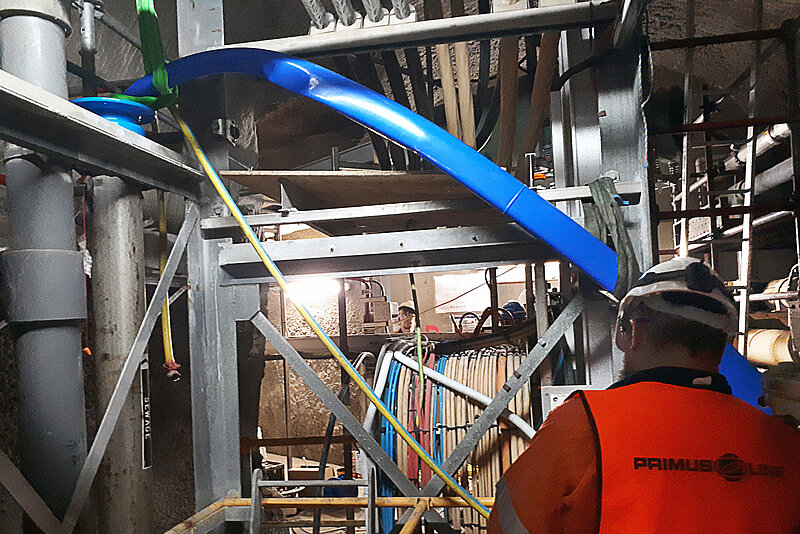

A DN 150 sump pump pipeline transporting sewage from a tunnel up to the surface was leaking at several points and therefore needed rehabilitation. With several other pipelines, this pipe is running through a very narrow vertical shaft which is only accessible by cramped ladders. Replacing this pipeline would have been a very time-consuming and complicated, if not impossible, undertaking. Hence, Sydney Water decided to reline the existing main with the Primus Line® system. The Primus Line technology has already been used for several other potable water rehabilitation projects with Sydney Water and is also on the list of deemed-to-comply products for pipeline rehabilitation of Sydney Water. This is the first project where Sydney Water used the Primus Line® system in a sewer main.

Sydney Water assigned the works to Primus Line’s local partner company Interflow.

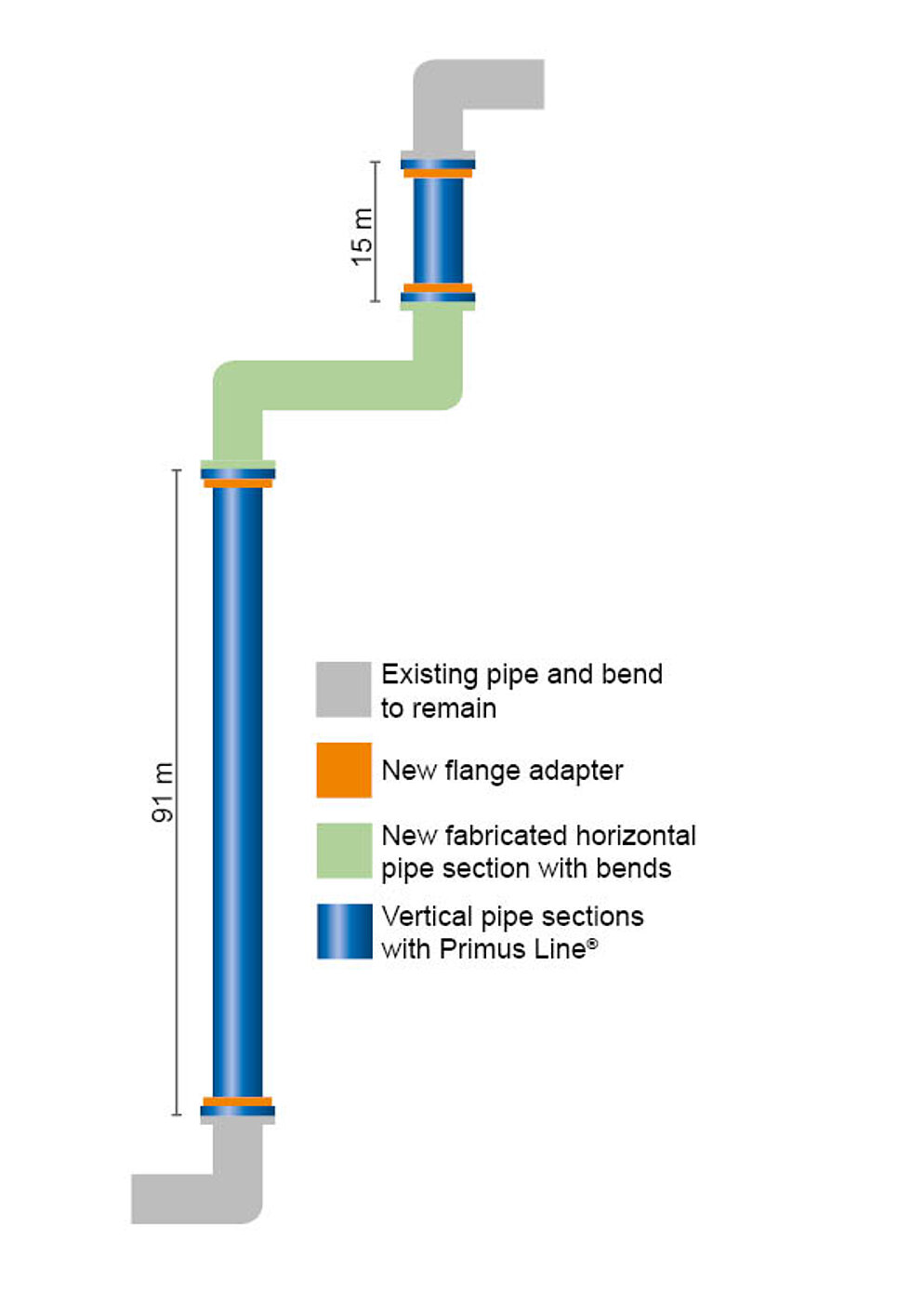

In a first step, the pipe was drained and small pipe cutouts were being created to grant access to the main. Coarse cleaning was performed by water jetting and the clean inner surface was subsequently verified by inserting a CCTV from the top of the pipeline. The rehabilitation itself was performed in two sections of 91 and 15 metres.

The Primus Liner arrived pre-folded on a round transport reel with a diameter of 1,400 millimetres. As the pipe to be rehabilitated was located in a constricted shaft which is only accessible through low walking tunnels and by narrow ladders, the transport reel had to be stored more than 75 metres away from the access point to the pipeline. The team decided to unwind the liner from the transport reel, unroll it along the tunnel and drag the Primus Liner to the access point. The pre-folded Primus Liner DN 150 PN 25 was being fed into the pipeline from top to bottom, secured throughout the entire installation process by ropes and lashing straps so that the liner would not fall down into the shaft. The team used a pulley system to lower all necessary tools and fittings from the top of the shaft to the pipeline’s access points. After inflating the pre-folded Primus Liner with compressed air, flange adapters and Primus Line PN 16 end fittings were installed. The entire installation of Primus Line® could be realized within two working days.