The petrochemical plant was built in 1966 to produce petroleum derivatives. Currently, this plant has a production capacity of 120,000 tons of styrene-butadiene-styrene (SBS) and styrene-ethylene/butylene-styrene (SEBS) per year. For its operation, the petrochemical plant needs a continuous water flow for cooling and fire protection. Therefore, it has a water supply system made up of a pumping station, and a 6-kilometre main supply pipe: Its first 3,600 metres with a diameter of DN600 consist of concrete reinforced with a sheet metal jacket and asbestos cement. The following 2,400 metres are made of asbestos cement with a diameter of DN350.

The industrial water pipe with an age of nearly 50 years began to show symptoms of being close to the end of its life span due to successive leakages in recent years - particularly in the asbestos cement section. The fortuitous leakage of the concrete pipe at the beginning of and under the intersection with the RENFE railway platform accelerated the need to undertake actions.

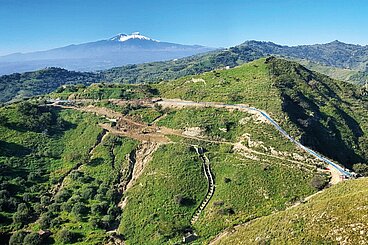

The DN600 pipeline of the initial section runs parallel to the platform of the Santander – Bilbao railway line, so any intervention in this area requires special access permits. This is the reason why a construction system that would minimise the damage to that infrastructure had priority.