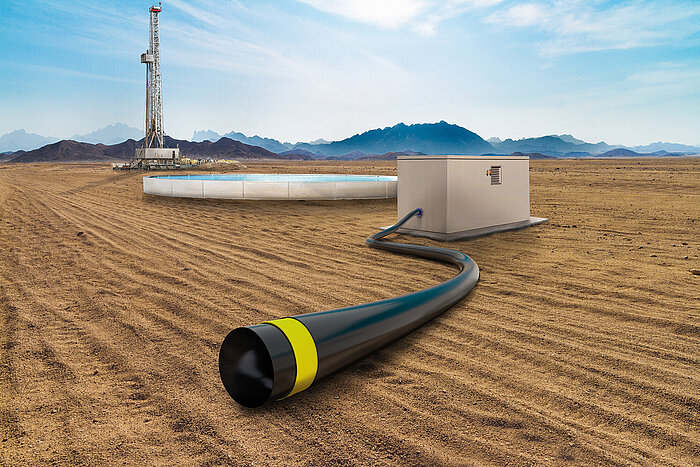

The history of Rädlinger primus line GmbH started with a brilliant idea: a unique system for the trenchless rehabilitation of pressure pipelines was born at the beginning of the 2000s in the Bavarian Forest. Innovation continues to be the biggest asset of the meanwhile internationally acting enterprise. So it is not surprising that a new further development is now ready for the market: Primus Line® Overland Piping stands for the safe transport of hazardous liquids everywhere where temporary lines are requested. So Primus Line® Overland Piping has for example been approved for the transport for fracking water in British Columbia and Alberta.

Companies from most various fields of activity sometimes are confronted with the problem to have transported large amounts of hazardous fluids from A to B for a relatively short period of time, later from A to C or even between to completely other points. Such temporary projects cause high ongoing expenses for the repeated mounting and dismantling of steel or HDPE pipes. The use of trucks, if possible at all, consumes fuel and personnel costs, unexpected accidents raise the operating costs as well.

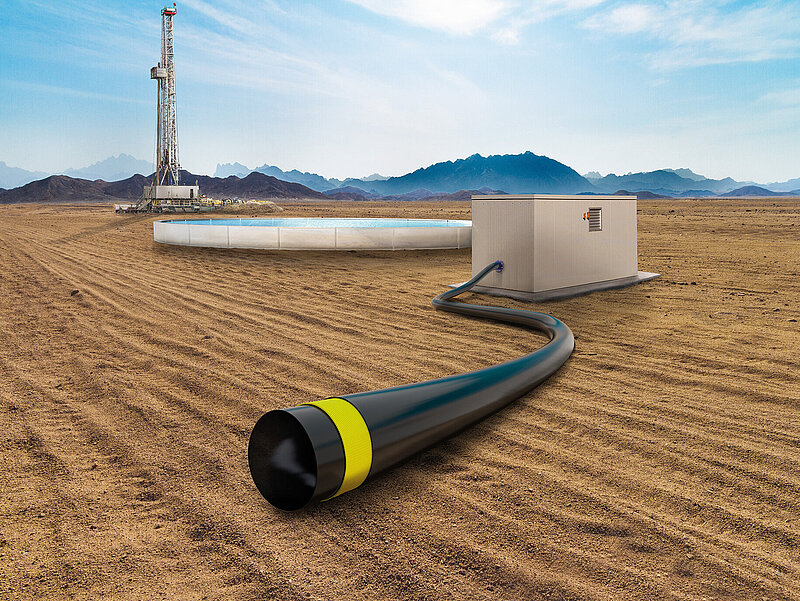

Primus Line® Overland Piping is the ideal solution for such applications, for example as safe and clean technology for the transport of fracking water. For its installation, it is just unrolled from its reel along the desired track; several hundred metres can be laid in a piece within minutes, completely without welding. Its installation can be executed in all weathers. Bends are also no problem for Primus Line® Overland Piping. After operation, it can be rolled up and re-used.

A core of seamlessly woven aramid makes Primus Line® Overland Piping extremely resistant. During its first operations, it was rolled over by loaded tankers without any damage to the liner being detected – even during subsequent laboratory tests monitored by an independent body.

Primus Line® Overland Piping stands out from the various lay-flat hoses by its resistance. These systems fail too often and thus cause severe damage to the environment. This is the reason why they are not approved for the transport of hazardous liquids in some countries. The Primus Liner, however, is characterised by reliability and safety which it has proven for almost 20 years in the field of trenchless rehabilitation of oil, gas and water pressure pipelines.

In contrast to the Primus Line® systems for gas, water and oil, the outer layer of the Primus Line® Overland Piping liner is also made of TPU, making it not only more resistant to chemicals and abrasion, but also more flexible. A black outer colour furthermore ensures UV resistance.

A high-end product naturally has its price. But after only four applications, Primus Line® Overland Piping exceeds the break-even point compared to HDPE pipes – with the difference that it can be used almost as often as required for 20 years. A worthwhile investment!

Technical details on Primus Line® Overland Piping

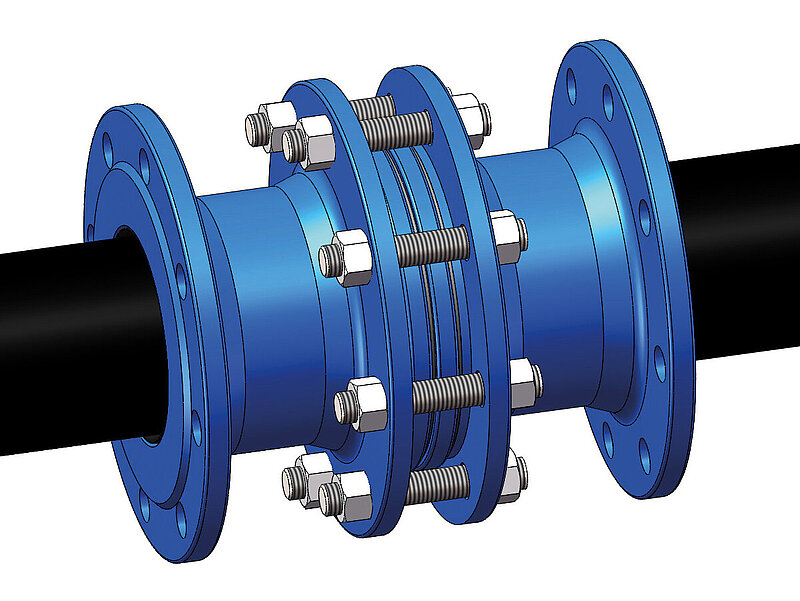

For installation, the liner will be fitted into the pipe system with specially designed and manufactured connectors that are approved for pressures up to PN 16. Primus Line® Overland Piping is produced in sizes between DN 150 and DN 300.

Learn more about Primus Line® Overland Piping