The reduction of greenhouse gases including carbon emissions is becoming increasingly important these days and is more present in peoples’ heads not least through the Fridays for Future movement. Emissions can also be saved in the construction sector and especially in the renovation of pressure pipelines. Primus Line installation partner Sinzatec from Spain used a carbon footprint calculator for trenchless technologies to determine the savings on a project near Madrid – with amazing results.

Recent pipe breaks in an old DN 400 drinking water main made its rehabilitation necessary. This asbestos cement main supplies water to various villages in the Madrid mountains near the Guadarrama National Park. The water supply for the residents was already temporarily interrupted.

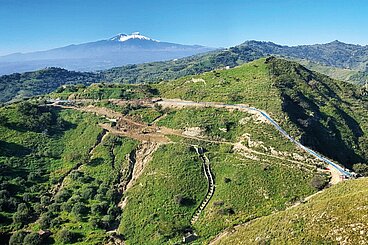

Renovation started with a first section of 700 m of the 3.4 km long water main. Due to the rocky landscape and the geology of the terrain, an open construction would have been very difficult and costly. In addition, the expected construction time would have been much longer resulting in the risk of further water supply interruption. So the water main was finally rehabilitated with Primus Line® in just four days.

For their carbon footprint calculation, Sinzatec compared trenchless construction with Primus Line® to the conventional open trench method, consisting of opening the trench, transporting the extracted material and backfilling the trench with new material. In the calculation, a lot of factors play an important role such as

- the amount of material to be removed

- fuel consumption of the construction equipment

- location of the construction site in combination with the required transport routes

- the number of necessary truck loads

- the soil type and

- the number of excavations required for connection or valves.

This constitutes the basis to determine the reduction of greenhouse gas in tons of carbon dioxide equivalent (tCO2e), the savings of diesel fuel and the reduction of the number of truck loads.

The analysis showed a significant reduction of approximately 86% in carbon emissions. This is mainly due to the lower number of truck loads required (minus 99%), but also to the much shorter use of excavators when digging the trenches and construction pits.

At the same time, this leads to a significant saving in fuel consumption (minus 87%), since the use of construction machinery and necessary equipment is cut down to a minimum.

Despite these advantages, as of 2020, less than 5% of the rehabilitation projects in Spain are carried out with trenchless technologies. But since the reduction of greenhouse gases is moving more and more into the focus of people and politics, trenchless technologies will certainly play a more important role in the future. Trenchless rehabilitation methods such as Primus Line® can help to improve the ecological footprint significantly and thus achieve the climate goals set.