Sydney Water Construction, an enterprise belonging to the Sydney Water Corporation (SWC), acts as an installation partner for Primus Line® in Australia. As a state enterprise, SWC provides the Sydney area with drinking water. What’s more, it delivers for example purified water via steel piping to the biggest steel manufacturer “down under”.

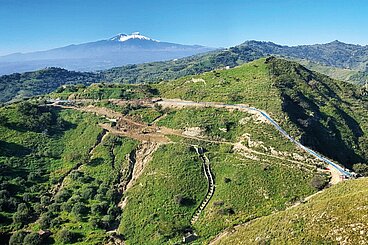

In the first half of 2017, this several kilometres long high-pressure main pipeline, with a diameter of DN 500 and an operating pressure of 14 bars, suffered a substantial defect near a large railway crossing in Cringila (almost 100 kilometres south of Sydney). To get to the root of the cause, SWC immediately shut off the main pipeline. Water supply to the steelworks initially continued through another pipeline – however, for SWC this was only an interim solution, also due to the cost. The defective high pressure pipeline had to be rehabilitated as some parts lay above ground and effluent water had damaged its thrust blocks through erosion.

Primus Line®, the method of choice for rehabilitation

In the preliminary stages of rehabilitation, SWC ran through various possible methods: the cooperation partners ruled out the horizontal drilling technique from the outset for reasons of cost and protection of the environment, as the main pipeline runs at one end near a creek, a bridge and other utility services. The second possibility: constructing and building a pipe bridge. This option was likewise costly and too much time would elapse for implementation. Conventional rehabilitation measures were also out of the question as the main pipeline had an operating pressure of 14 bars, a series of 45 degree bends and one 90 degree bend.

SWC was already aware of the cost-effective, Kevlar® reinforced Primus Line® system from other trenchless rehabilitation projects of high pressure pipelines with sharp bends. Hence, in this case, it was the method of choice. Primus Line® was able to pass through the 90 degree bend, sustain the 14 bar operating pressure, only took 20 minutes to install and did not need to be cured.

Designed for high pressure

In the preliminary stages of rehabilitation of the 52 metre long pipe section, the engineers at Primus Line established that the 90 degree bend could be rehabilitated with a DN 400 Primus Liner with double-layer Kevlar reinforcement. This liner is operable independently of carrier pipes with an operating pressure of 20 bars, even through a 90 degree bend, and has a burst pressure of 100 bars.

What was exciting about this project was that SWC carried out this installation in October 2017 fully self-sufficiently. It was only at the beginning of the same year that trainers from Primus Line Germany had trained SWC employees on site in theory and practice. It is a great advantage of the Primus Line® system that no investment in additional equipment is subsequently necessary: It is pulled in by an approved winch and brought into shape with an oil-free air compressor.