Situation

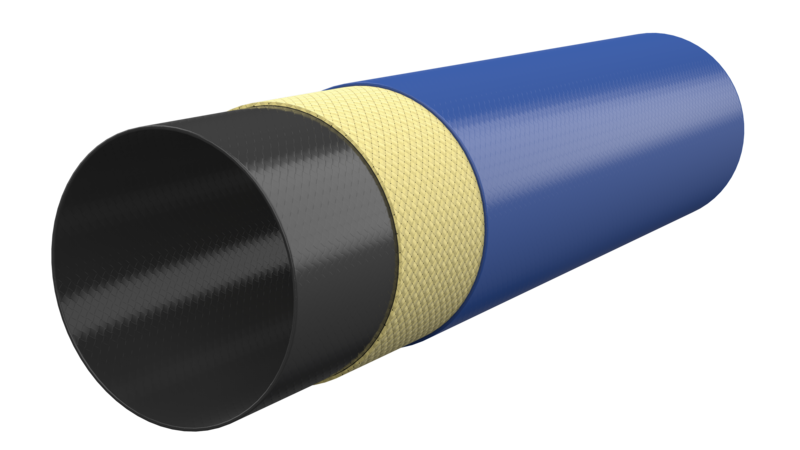

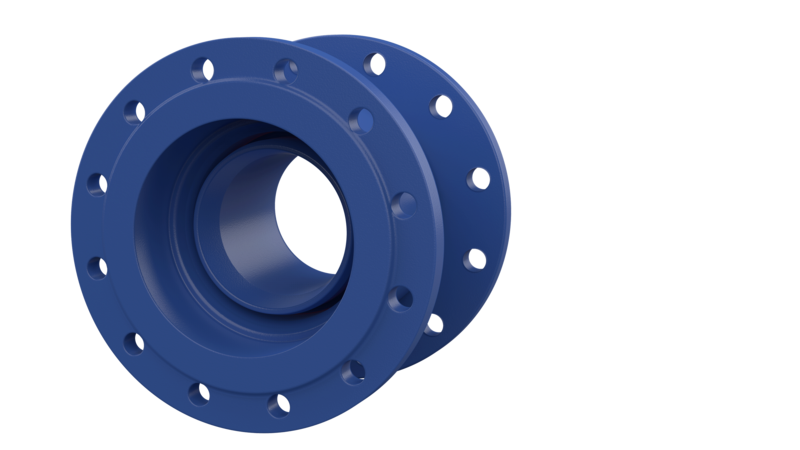

KEM ONE, one of Europe’s largest vinyl producers, has rehabilitated an eight-kilometre section of a transport pipeline for brine with a total length of 92 kilometres between its saline in Vauvert and the production plant in Fos-sur-Mer. In order to maintain the brine supply to the plant and thus also production, the transport pipeline was rehabilitated in eight sections of one kilometre each. To do so, a bypass, i. e. Primus Line® Overland Piping is used for every rehabilitation section.