Functional fire-extinguishing systems are the prerequisite for an operating permit in the industrial sector such as chemical plants, refineries or airports,. In order to maintain it permanently, operators test their fire water mains regularly. Any weak points or damages discovered in this process have to remedied to ensure that the lines function properly in the event of fire.

Technical challenges for operators

With regard to the technology applied, operators are confronted with a variety of challenges: The fire water mains have to be checked regularly for leaks. In the case of above-ground pipelines, the operators periodically carry out flow and flow rate measurements. In the case of underground fire water mains, however, tests may lead to pipeline breaks, because in this deployment simulation – as in a hazardous situation – the fire water is forced through the pipelines at increased pressure. Already damaged, ageing or even corroded pipelines cannot withstand this pressure. Repairs to these damages are usually only a short-term remedy, since the pressure in the pipe seeks the next weak point, causing further damages.

If operators in the industrial sector use seawater or salt water for firefighting, its transport can affect the pipeline and make it corrode – for example in the case of steel pipes or cast iron pipes without a cement lining. These can then no longer absorb the operating pressure.

„Accessibility for the rehabilitation of fire water mains also plays a role in industrial plants,” informs Andreas Gross, head of the Water International business unit with Rädlinger primus line GmbH. “The pipelines are frequently laid under access roads, larger asphalt surfaces or embedded in concrete. Or there is a multitude of other transport and supply lines in the facility. In addition, the fire water mains branch out to hydrants, for example. In these cases, an open-trench method with heavy equipment such as excavators would involve high costs and possibly restricted operation, due to applicable strict safety regulations and protocols,” he explains.

Economic challenges for operators

The economic challenges include, above all, repairs of suddenly occurring damages. These are cost-intensive and – as mentioned – usually only successful for a short time.

Permits to enter the site, scheduling of repair activities and their impact on productive operation are also issues operators have to consider.

Trenchless systems preferred

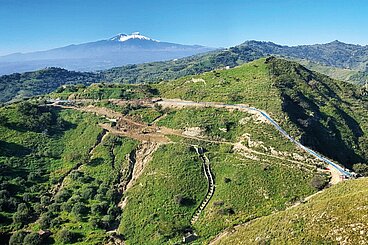

„Given the complexity of technical and economic factors in the rehabilitation of fire water mains, trenchless methods score points,” Gross is convinced: Seamlessly manufactured hose liners such as Primus Line® only require small construction pits at the beginning and end of the rehabilitation section to pull it into the pipe to be renovated. These pits can be dug out with a suction excavator or even by hand in extreme cases. Likewise, existing shafts can serve as access points.

Furthermore, insertion only needs few equipment – a pulling winch is sufficient. Few equipment also ties up few staff. And the insertion speed of up to ten metres per minute reduces installation times to a minimum.

If damage occurs suddenly, refurbishment can be carried out quickly, especially if hose liners such as Primus Line® are stored on site. In addition, this also enables regular maintenance in maintenance windows that are available at short notice. This does not even require external installation personnel: Rädlinger primus line GmbH trains the maintenance staff of the operators accordingly, so that they can carry out the renovation activities themselves.

There are no follow-up costs after a rehabilitation with Primus Line®, since the manufacturer has designed its product for a service life of 50 years. Primus Line® proves its durability at an Austrian airport. In a refinery on the airport grounds, 4,265 feet of fire water mains were rehabilitated with the inliner a good fifteen years ago. They are still functioning perfectly.

It is not uncommon for fire water mains to run also in horizontal or vertical 90° bends. Under appropriate conditions, the flexible Primus Liner masters up to four 90° bends with r = 1.5 x D in one rehabilitation section. Bends up to 45° can be negotiated without problems. The installations teams on site react just as flexibly: As-built plans in industrial facilities are frequently not up to date. Due to the structural conditions or the assignment to danger zones, it is often not permitted to inspect the pipes to be rehabilitated with a camera prior to rehabilitation start. Obstacles or discrepancies are thus only detected during liner insertion on site.

„Since safety is the top priority for operators of industrial plants, we had have our hose liner tested several times for fire resistance in the presence of independent testing companies,” Gross explains and specifies: “The result is reassuring: If the pipe is filled with fire water, this has a cooling effect and the liner shows scorch marks at most at the outer of its three layers. The inner layer and the reinforcing aramid fabric, however, are not damaged by either selective or extensive heat input. Functionality is ensured even if the fire water main itself should be affected by the fire.”

Bottom line: reduced investment and operating expenses

The advantages of trenchless systems such as Primus Line® for the rehabilitation of fire water mains are reflected in a significant reduction in costs. A refinery operator compared in a study the expenses for repair work using conventional construction methods and Primus Line® at one of his sites – with amazing results: Trenchless rehabilitation reduces the costs per metre to around half, whereas the metres of pipe rehabilitated per month increases by a factor of ten to fifteen.

The same operator accumulated also the repair costs including follow-up costs for a three-digit number of leaks at one location over a period of thirteen years. The result was an amount in the low double-digit millions. Rehabilitation of these leaks with Primus Line® would limit the renovation work to five years, reduce the investment sum for the execution period by a third and would not entail any follow-up costs.

„Pipe rehabilitation with Primus Line® increases efficiency, reduces investment and operating costs and extends the service life of the fire water mains – convincing arguments for trenchless methods,” summarises Gross.

Read another article "Rehabilitation of fire water mains with trenchless methods – a recipe for success"