Production and quality

Continuous quality control accompanies the entire manufacturing process of the Primus Line® technology and ensures the safety and long service life of the system.

Top-quality raw materials

We set high standards in the procurement of raw materials and only work with renowned manufacturers. We carefully check the quality of all incoming goods.

The material requirements for water, gas and oil pipes are demanding. Nevertheless, Primus Line® has numerous certifications in accordance with demanding international standards.

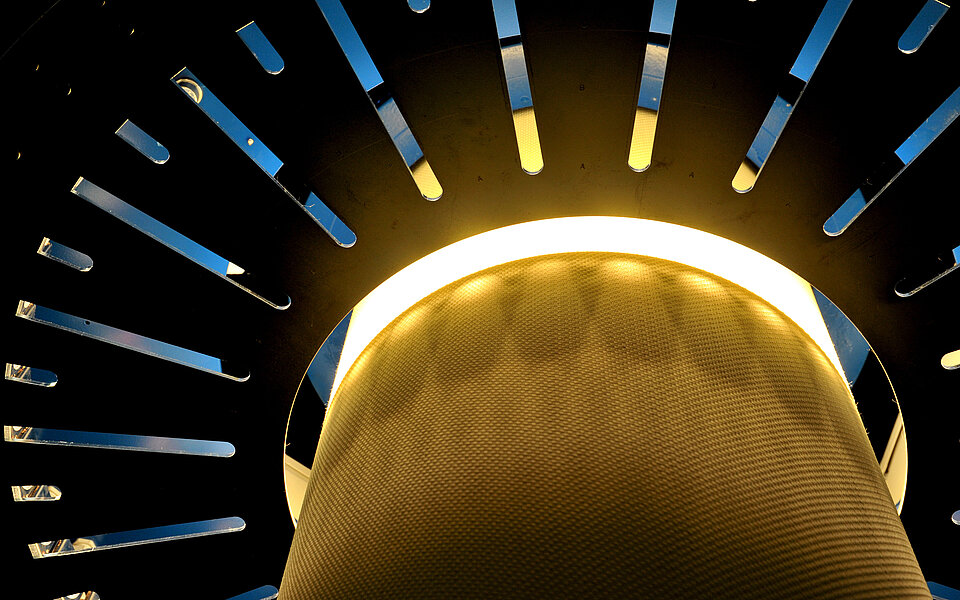

Tailor-made manufacturing technology

The centrepiece of our production is the circular loom developed by Primus Line. With its high-precision electronic controls, it weaves a seamless and absolutely twist-free fabric from Kevlar®. This is the basis for the extrusion process that applies the inner and outer layers made of polyethylene (PE) or thermoplastic polyurethane (TPU). The almost 65-foot high vertical production line combines the three raw materials to a robust three-layered liner.

Our R&D department is constantly working on the further development of the Primus Line® system and the manufacturing technology. This permits to use new polymers for inner and outer layers and offers the opportunity to further optimise the layers or develop them for entirely new fields of application.

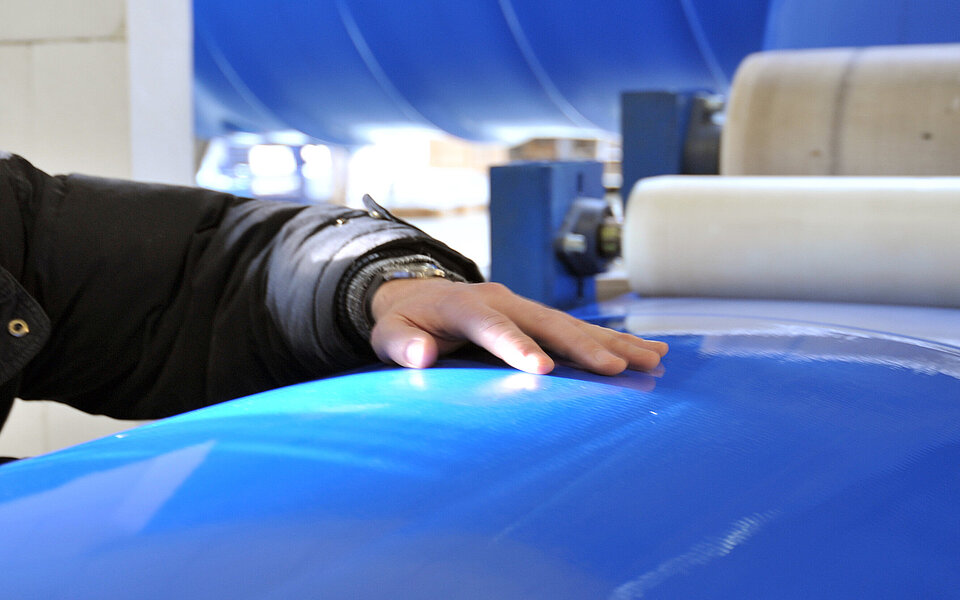

Quality control

Primus Line® is subject to continuous quality control with optoelectronic measuring instruments. These capture all process parameters and allow a continuous control of the consistency and wall thickness of the individual liner layers. In addition, every production batch receives a batch ID for an unambiguous traceability and undergoes a burst pressure test that reliably confirms the maximum operating pressure. the connectors are subject to a thorough visual inspection. Customers receive all results summarised in a final quality documentation.