Liner

The liner is one of the two key components of Primus Line®.

As an installation solution it serves the rehabilitate pressure pipes and stand-alone it functions as a robust flexible line. The ability to be self-supporting allows it to be used without impregnation, curing or gluing.

A liner is a fabric hose that is inserted into a damaged or leaky pipeline to rehabilitate it trenchlessly from inside. Liners are also called inliners. Depending on the lining method, the differ in their structure.

In case of lining with inserted hoses, the liner has a fabric core made of aramid fibres, which is coated with thermoplastics such as e. g. PE (polyethylene). After insertion, this flexible pipe will be brought into its round shape by means of compressed air and then remains freely in the host pipe. This liner can reach a maximum length of 8,200 feet.

Other methods such as lining with cured-in place pipes or lining with adhesive-backed hoses rely on a textile hose made of glass-fibre reinforced plastic (GRP) or needle felt which is soaked with reactive resin. After insertion, it hardens by means of warmth or UV light and is then firmly connected to the old pipe. These inliners allow lengths between 1,960 and 2,460 feet.

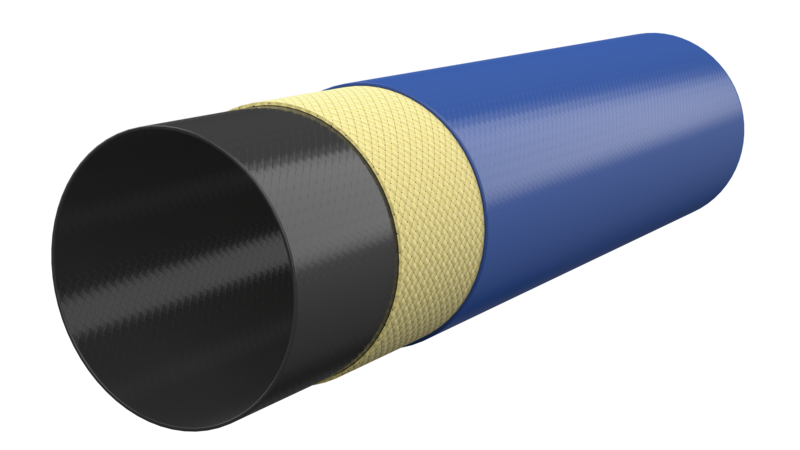

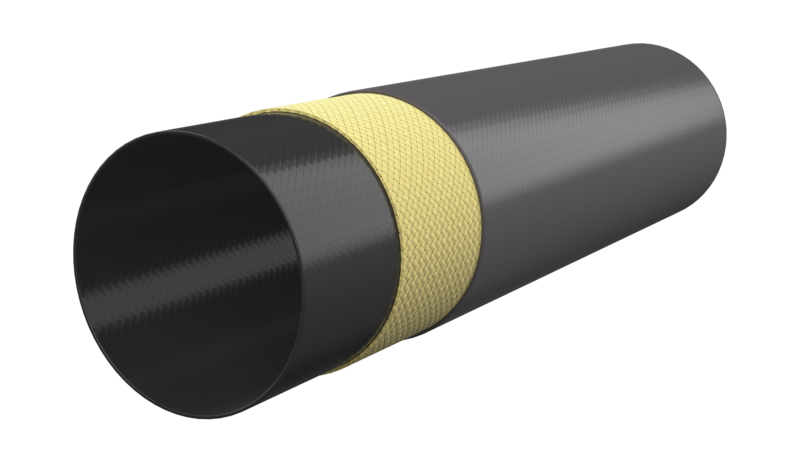

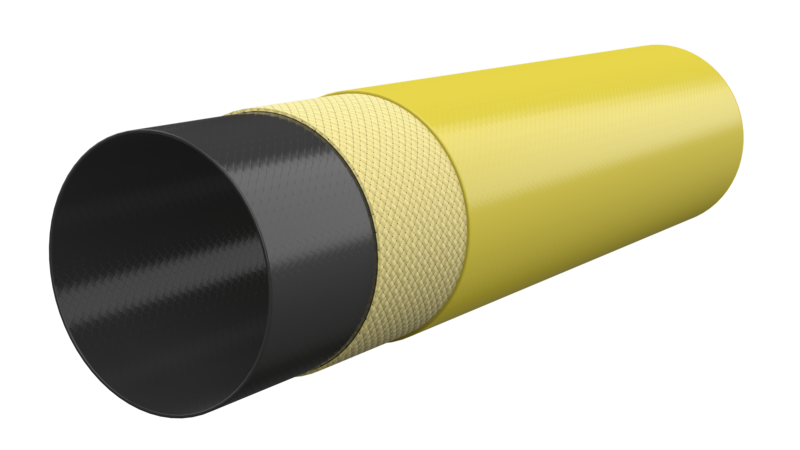

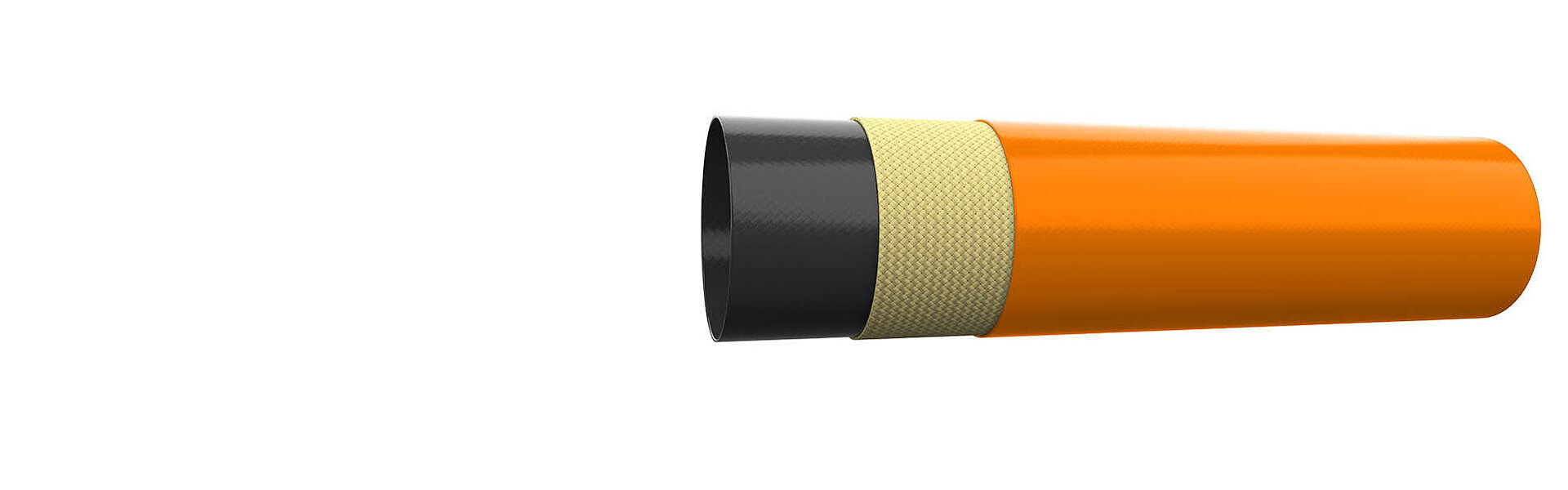

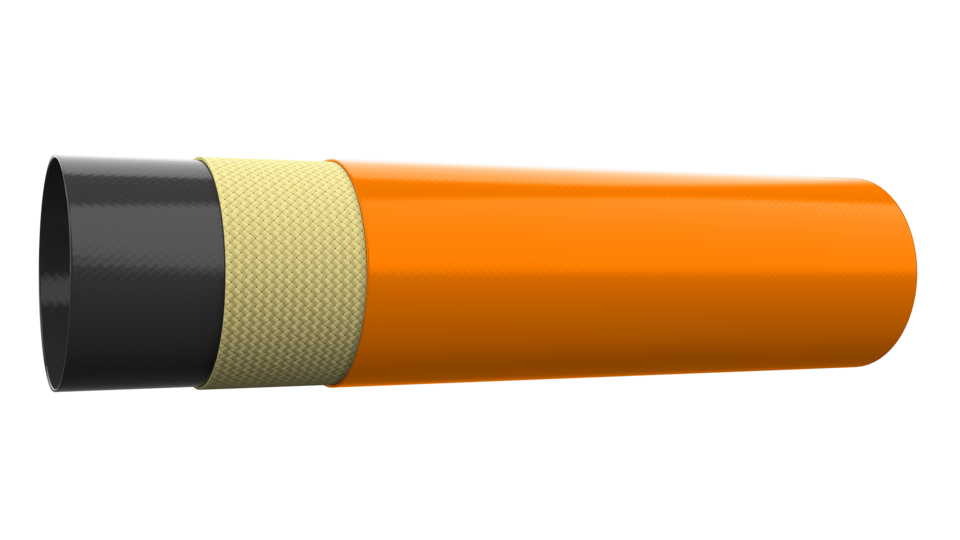

Versatility through three-layered composition

Inner layer

- High chemical resistance

- High abrasion resistance

- Corrosion resistant

Reinforcement

- Accommodates the operating pressure by itself

- Up to 10 times stronger than steel of equal weight

Outer layer

- High abrasion resistance, protecting the fabric during installation and operation

- High UV resistance

We exclusively utilise top-quality materials

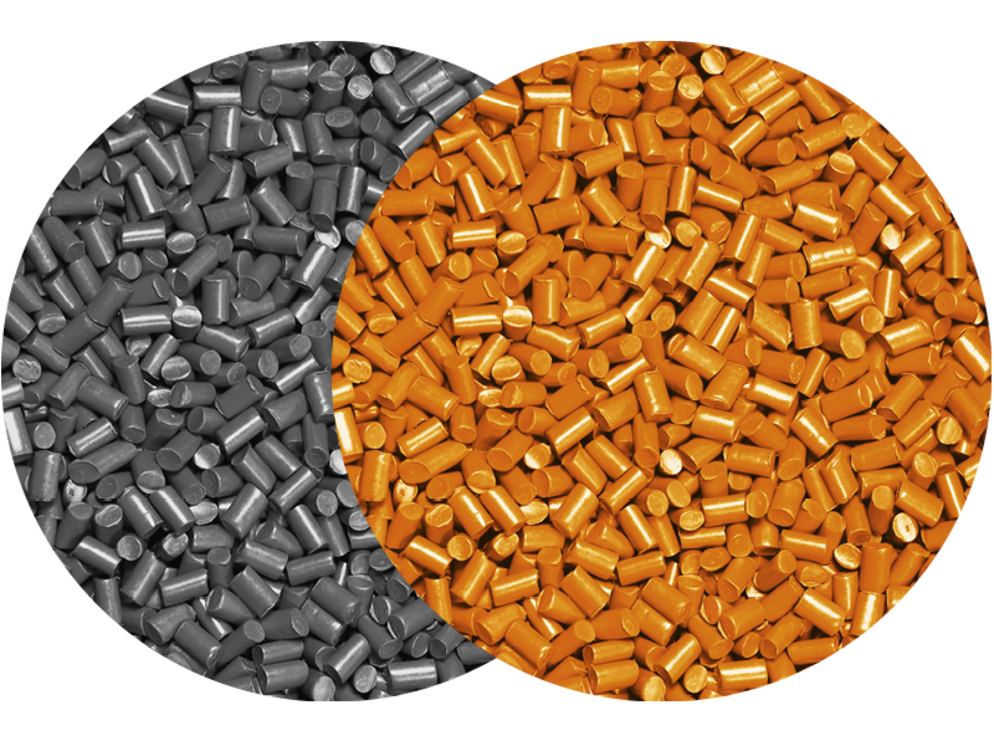

Kevlar®

Kevlar® is a high-strength and leightweight para-aramid synthetic fibre known for its exceptional tensile strength and durability.

It consists of long and regularly orientated polymer chains. Due to their chemical structure and orientation, a large number of hydrogen bonds can form between the polymer chains, which contribute significantly to the properties of Kevlar® fibres.

PE

Thanks to its flexibility, polyethylene enables easy installation. In addition, the high abrasion resistance of polyethylene contributes significantly to the durability of the pipework.

This material ensures long-lasting protection and a secure seal, thus making it a reliable and robust solution for inner and outer layers of our flexible liner.

TPU

Thermoplastic polyurethane offers a high level of flexibility, impact strength and chemical resistance, ensuring first-class protection under extreme conditions.

In addition, TPU has UV and temperature resistance, which is crucial for long-lasting durability and protection of pipework in various applications. Its robustness offers a reliable and durable solution for different industrial and infastructure requirements.