Sustainability

Location-neutral by 2030

As a family-owned company, sustainability plays a decisive role for us in all respects. That is why we have our carbon footprint determined at regular intervals by independent service providers. Based on this data, our internal energy team works continuously to improve energy efficiency with the aim of achieving location neutrality by 2030.

GHG inventory

Excerpt from the greenhouse gas inventory

| Scopes | Description | tCO2e |

|---|---|---|

| Scope 1 | Direct emissions | 243 |

| Scope 2 | Indirect and upstream emissions | 445 |

| Scope 3 | Indirect, upstream and downstream emissions (Purchased goods and services 3,701 tCO2e Other Scope 3 emissions 519 tCO2e) | 4,220 |

The analysis and differentiation of the Primus Line data and the conversion of the emissions into CO2 equivalents (CO2e) results in the following greenhouse gas (GHG) inventory for 2022*:

* determined by the independent external service provider ERCE

4,908 tCO2e

This corresponds to an output ...

of about 1,385 EU households

– which is less than 0.001 per cent of all EU households

of a two-week cruise

of 1,308 two-week holidays to Thailand from Germany

Energy management

For an active energy management in accordance with ISO 50001, a twelve-member energy team at the Werner Rädlinger Group continuously identifies measures to improve energy efficiency. The central objectives are to continuously save energy and increase energy self-sufficiency in order to become less dependent on fossil fuels.

This has already resulted in a specific energy saving of 20.4 per cent from 2021 to 2022 in relation to turnover.

Moreover, the company wants to identify and qualify suppliers with a lower footprint – if this is possible. Currently, only a few suppliers have prepared their GHG inventory.

Current facts

Measures already realised

- 85 vehicles in the fleet; 30 of them e-cars

- 25 e-charging stations at the facility

- Replacement of electric and diesel forklifts with more efficient electric forklifts

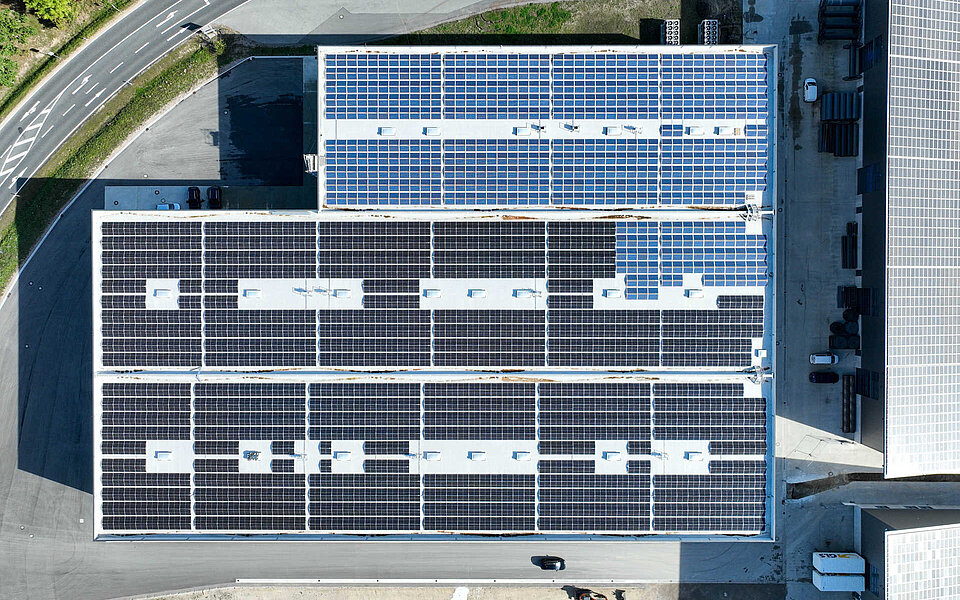

- 205 kWp output of the new photovoltaic system on the production building in Weiding. Own utilisation is around 22%. The remaining electricity is currently made available to the public grid.

- 800 kWp output of the new photovoltaic system on the new warehouse in Chammünster. Own utilisation is around 42%. The remaining electricity is currently made available to the public grid.

- 4.35 MWp outpout of all photovoltaic systems belonging to the Werner Rädlinger Group including grid feed.

- Heat recovery and heat pump technology for in-house energy utilisation in the Primus Line logistics halls.

TRENCHLESS PIPE REHABILITATION

How does Primus Line® technology contribute to greater sustainability?

Primus Line® is an environmentally orientated and emission-saving technology for the rehabilitation of pipelines. The trenchless method reduces impacts on the environment as well as noise, fine dust and greenhouse gas emissions to a minimum.