Karriere

Benefits

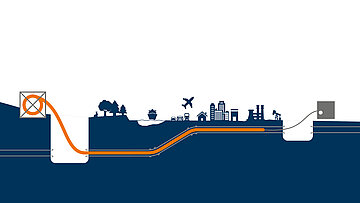

Efficiency

- Installation through multiple bends up to 90 degrees

- Withstands thermal expansion of the host pipe and ground movement

- Burst pressure rates up to 2988 psi

- Operating pressure up to 1189 psi

- Independet of host pipe

- No curing, steaming, adhesion or thermal treatment of the liner after installation required

- Almost independent of weather conditions during installation

Environmentally orientated

- Minimum use of machinery: This can result in a significant reduction of the carbon footprint

- Installation via small excavation pits, chambers and structures

- Decreased impact on traffic

- Only small construction site areas required

- Reduction of the on-site carbon footprint by up to 90 per cent compared to dig and lay

- We also pay attention to sustainability as a company