HDPE vs. Primus Line®

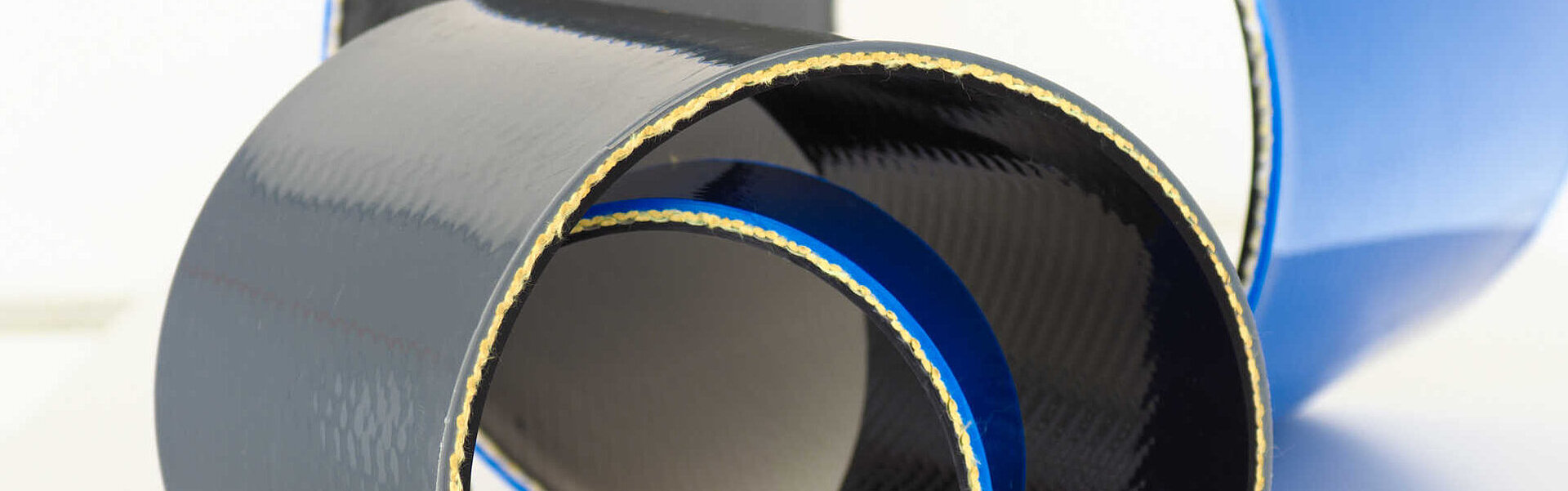

Primus Line® offers you an efficient and environmentally orientated alternative.

Hard-density polyethylene pipes (HDPE pipes) are often the first choice for installing above-ground pipelines. Here you will find a comparison of the properties of HDPE pipes and our innovative Primus Line® Overland Piping system:

Requirements for constructing 3.7 miles of pipeline:

The significant reduction in construction time, the reduced transport costs and the reduced need for tools will considerably increase the efficiency of your projects.

| HDPE | Primus Line® Overland Piping | |

|---|---|---|

| Mobilisation |

|

|

| Equipment |

|

|

| Installation time with one crew |

|

|

| Removal time |

|

|

| Fusion welding |

|

|

| Manpower |

|

|

| Cold weather application |

|

|

Connections needed on 3.7 miles of temporary surface pipeline:

Another decisive advantage is the reduction of connection points in the transport line.

300 - 500 conventional pipe connections

6 - 12 Primus Line connectors

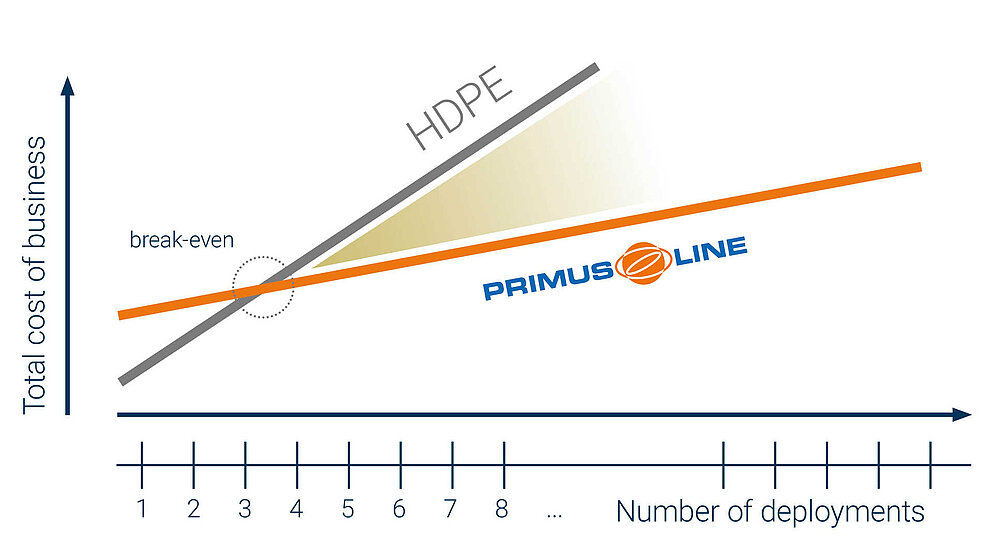

Total cost:

The more frequently the system is used, the greater the savings and benefits. Rely on the Primus Line® system and benefit from maximum cost-effectiveness.