The Challenge

The City of Seattle faced a significant challenge: a 1,785-foot section of its potable water transmission pipeline under and across a heavily used railroad had become compromised due to age and mechanical faults. The pipeline of both 20-inch and 16-inch diameter concrete mortar pipes had leaks at the joints, leading to soil erosion and water loss. Additionally, the pipeline featured several bends, including a 45-degree bend and multiple 22-degree bends, further complicating the rehabilitation efforts.

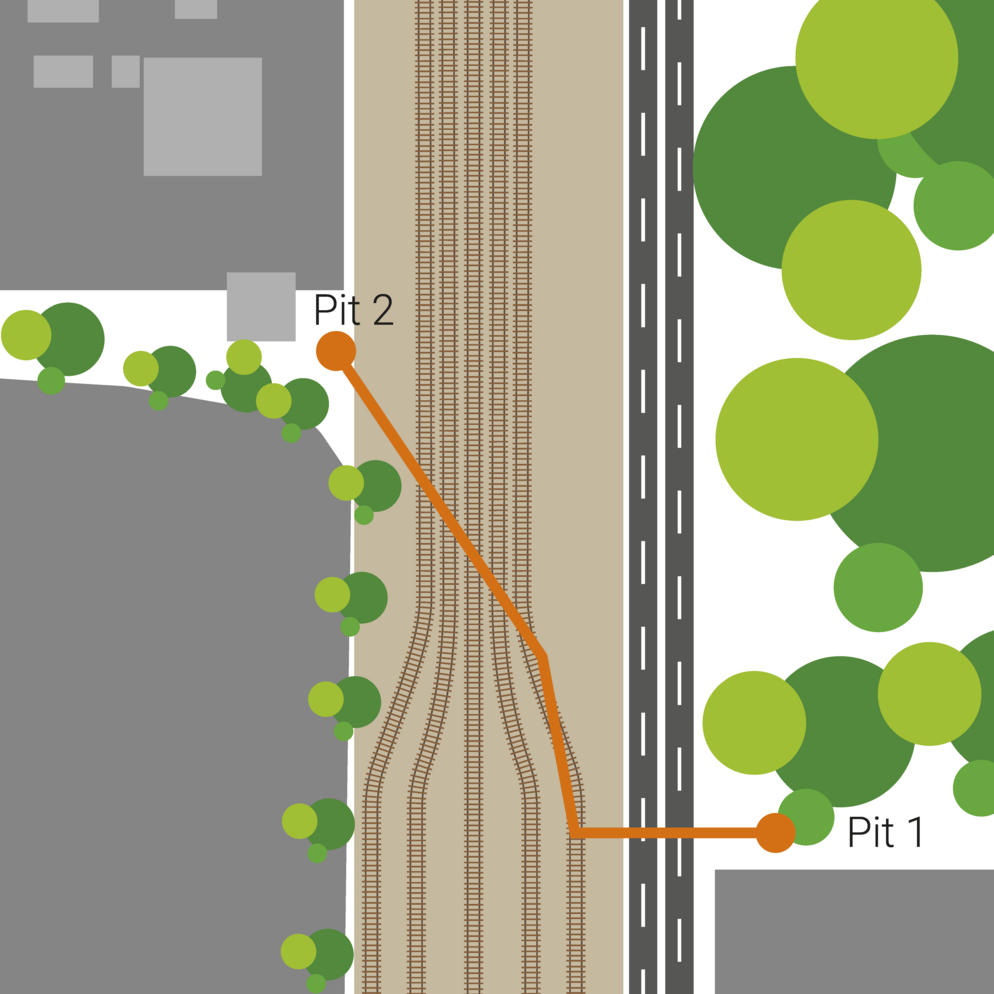

Given the urban location of the pipeline, with access points near an electric vehicle charging station and within a residential area, the solution needed to be minimally invasive. Furthermore, the pipeline's operation at 250 PSI, with a hydrostatic test requirement of 300 PSI, demanded a system that could handle high pressure while navigating the pipeline’s bends and transitions.