Situation

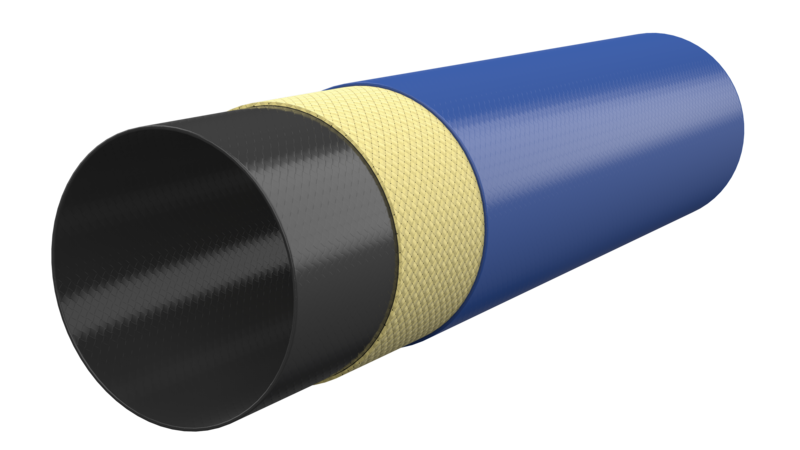

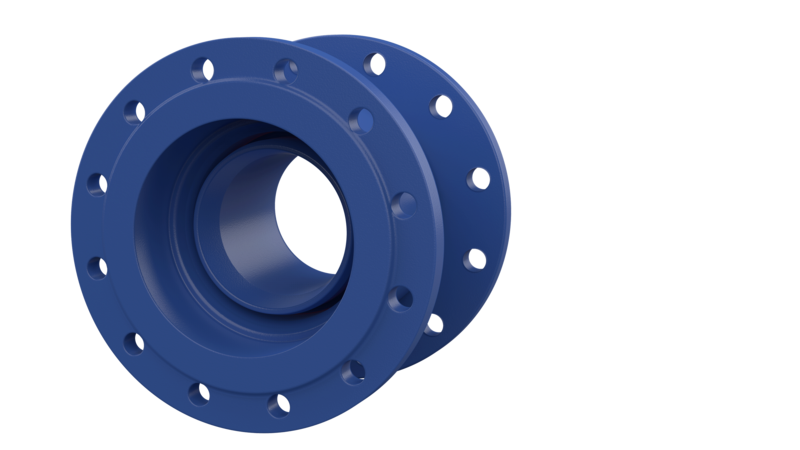

The operator identified leakages in a treated refinery waste water pipeline. This was the result of a significant amount of chlorine that had to be added to the transported waste water in order to comply with the district’s odor requirements. Local repairs with clamps were executed on a regular basis, however, at this point the pipe was due for overall rehabilitation.