Karriere

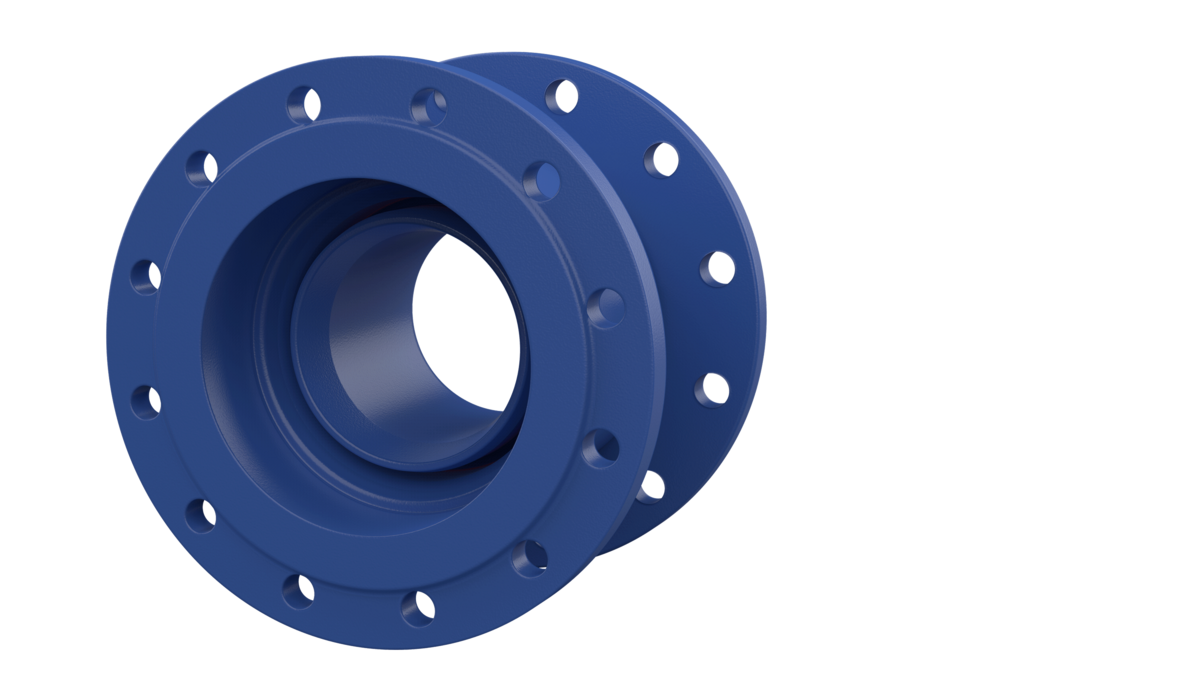

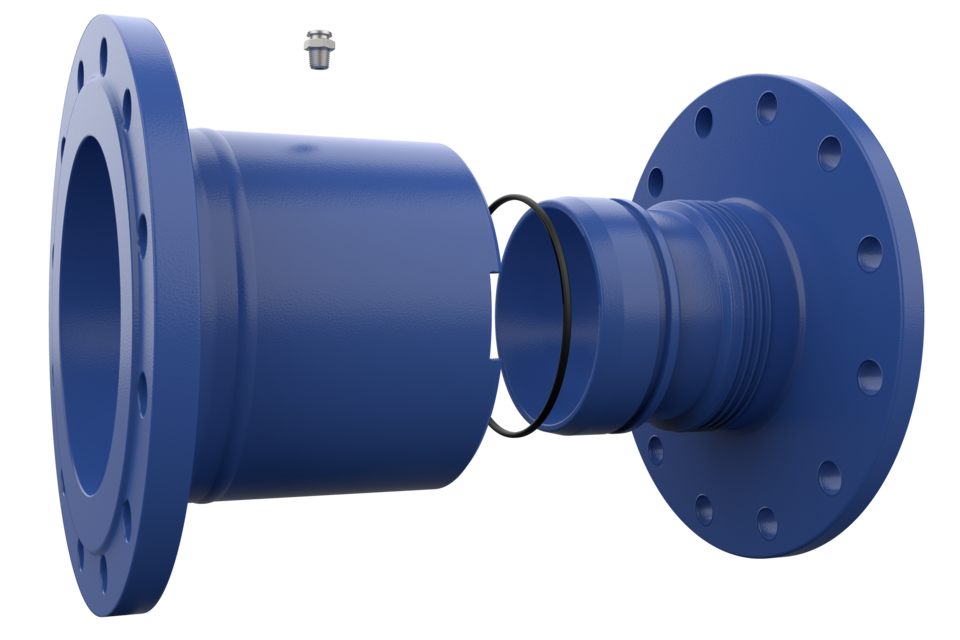

R-Connector | Resin

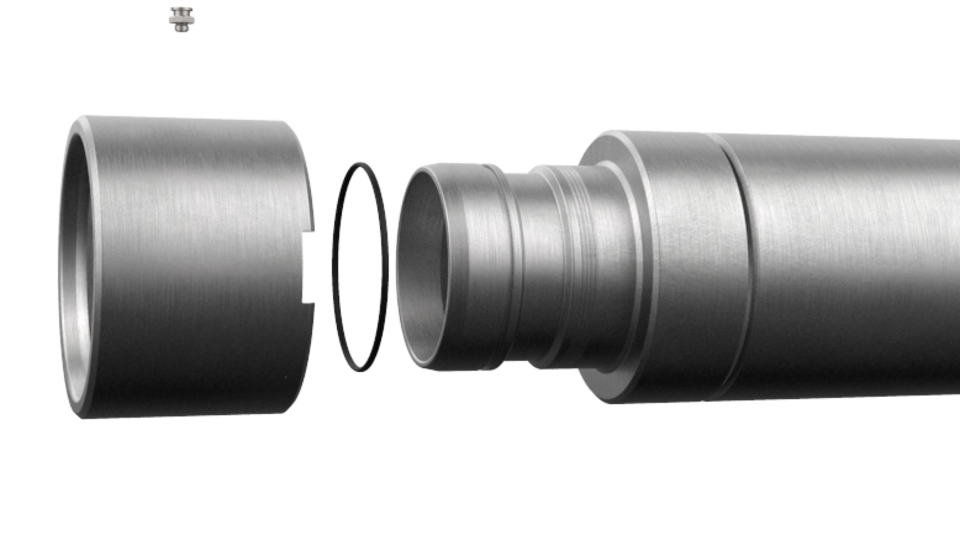

The principle of a tension-resistant connection between liner and R-Connector is always the same: The outer sleeve has an inner jacket made of malleable steel. Under high pressure, a two-component resin is pressed through the valve which presses the steel jacket and the liner into the profile of the core. This creates a durable and stable unit once the resin has hardened.

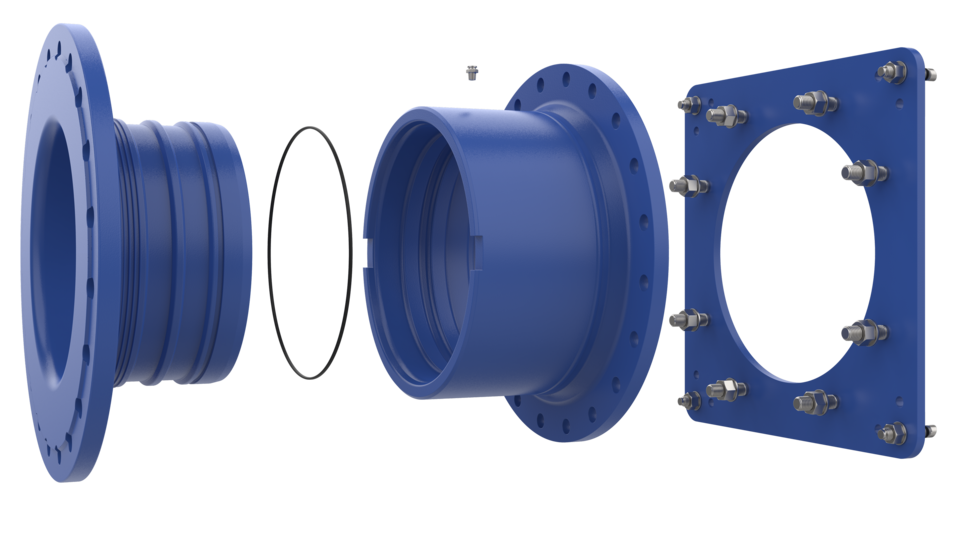

For wall mounting in manholes, the connector is also available with a mounting plate. Connectors with welded ends are also available. This makes this type the most flexible of the Primus Line® connectors.

Features

- Available as welded, forged or partially cast version

- DIN and ANSI materials available, material requests can be taken into account in the connector core

- Compatible with liner types ND, MD and HD

- Available in nominal sizes from 6 inches to 20 inches with flanges according to DIN, ANSI and AS4087

- Project-specific solutions are available on request

Connection with flange

Press sleeve with malleable steel jacket

Core

Gasket

Valve for pumping in two-component resin

Connection welded

Press sleeve

Gasket

Core

Valve

Connection with wall plate

Core

Gasket

Valve

Press sleeve

Wall plate

Variants

R

| Variant | Maximum operating pressure | Maximum operating temperature | Liner compatibility |

|---|---|---|---|

| DN 150 - DN 500 | 1.189 psi | 122 °F | ND, MD, HD |